Electrical maintenance contracts are pivotal in ensuring the functionality and safety of electrical systems across various settings. These contracts are agreements between a client and an electrical service provider, specifying the terms under which maintenance services will be carried out. The significance of these contracts lies in their ability to provide structured, regular maintenance, thereby preventing unexpected failures and ensuring compliance with safety standards. Understanding the different types of electrical maintenance contracts and their key components is essential for choosing the right agreement for your needs.

Types of Electrical Maintenance Contracts

Comprehensive Contracts

Comprehensive electrical maintenance contracts are the most all-encompassing option available. These contracts cover all aspects of an electrical system, including preventive maintenance, regular inspections, and emergency repairs. This type of contract is ideal for facilities that require constant monitoring and upkeep of their electrical systems to prevent any potential issues. By including a wide range of services, comprehensive contracts ensure that every part of the electrical system is maintained in optimal condition, significantly reducing the likelihood of unexpected breakdowns.

Preventive Maintenance Contracts

Preventive maintenance contracts focus specifically on routine inspections and upkeep. The primary goal of these contracts is to prevent equipment failures before they occur. Regular inspections, testing, and servicing are scheduled to ensure that all electrical components are functioning correctly. This proactive approach extends the life of the equipment and minimizes the need for emergency repairs. Preventive maintenance contracts are particularly beneficial for businesses that aim to maintain high operational efficiency and reduce long-term maintenance costs.

Emergency Maintenance Contracts

Emergency maintenance contracts provide immediate response services for unexpected electrical failures. These contracts are designed to minimize downtime and address urgent issues that could disrupt operations. Typically, emergency maintenance contracts guarantee a quick response time, ensuring that any electrical faults are promptly repaired. This type of contract is essential for facilities that cannot afford prolonged periods of inactivity due to electrical issues, such as hospitals, data centers, and manufacturing plants.

Key Components of Electrical Maintenance Contracts

Scope of Work

The scope of work is a detailed description of the services included in the electrical maintenance contract. It outlines the specific tasks that the service provider will perform, such as inspections, repairs, testing, and cleaning. A well-defined scope of work ensures that both parties have a clear understanding of their responsibilities and the extent of the services provided. This clarity helps in avoiding any disputes or misunderstandings during the contract period.

Equipment Covered

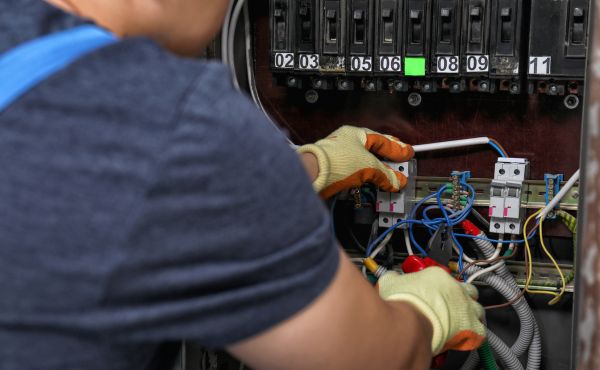

An essential component of any electrical maintenance contract is the list of equipment and systems covered. This list can include transformers, switchboards, generators, circuit breakers, and other critical components. By explicitly stating which equipment is covered, the contract ensures that all necessary parts of the electrical system receive the appropriate maintenance. This comprehensive coverage helps in maintaining the overall health of the electrical infrastructure.

Compliance and Safety

Ensuring compliance with local codes, industry standards, and manufacturer recommendations is a crucial aspect of electrical maintenance contracts. These contracts should include provisions that guarantee all work performed adheres to relevant safety and regulatory requirements. Compliance not only ensures the safety of the facility but also protects against potential legal and financial liabilities that may arise from non-compliance.

Service Schedules

The frequency and timing of maintenance visits are critical to the effectiveness of an electrical maintenance contract. Service schedules should be clearly outlined, specifying how often inspections and maintenance activities will take place. Regularly scheduled maintenance visits help in identifying and addressing potential issues before they escalate, ensuring consistent performance and safety of the electrical systems.

Benefits of Electrical Maintenance Contracts

Increased Equipment Longevity

One of the primary benefits of electrical maintenance contracts is the extension of equipment life. Regular maintenance helps in identifying and addressing minor issues before they become major problems. This proactive approach prevents costly breakdowns and ensures that electrical systems continue to operate efficiently for a longer period. By investing in regular maintenance, businesses can avoid the high costs associated with replacing equipment prematurely.

Safety Enhancements

Electrical maintenance contracts significantly enhance safety by reducing the risk of electrical fires and other hazards. Proactive maintenance ensures that all electrical components are functioning correctly and safely, minimizing the likelihood of accidents. This creates a safer environment for employees and customers, which is particularly important in settings where electrical safety is critical, such as industrial plants and commercial buildings.

Cost Savings

Preventive maintenance can lead to substantial cost savings by avoiding expensive emergency repairs and minimizing downtime. Regular maintenance activities are generally less costly than dealing with major breakdowns and the associated disruptions to operations. By preventing issues before they occur, businesses can manage their maintenance budgets more effectively and avoid unexpected expenses.

Improved Reliability

Consistent maintenance ensures that electrical systems operate efficiently and reliably. Regular inspections and upkeep help in maintaining the performance of electrical components, reducing the risk of unexpected failures. Improved reliability is crucial for businesses that rely heavily on their electrical systems for daily operations, as it ensures uninterrupted productivity and service delivery.

Choosing the Right Electrical Maintenance Contract

Choosing the right electrical maintenance contract starts with assessing the specific needs of your facility. Evaluating factors such as the complexity of your electrical systems, the criticality of continuous operation, and your budget will help in determining the most suitable type of contract. Understanding your unique requirements ensures that you select a contract that provides the necessary level of service and protection.

Contractor Selection

Selecting a reliable electrical contractor is essential for the success of your maintenance contract. Key criteria to consider include the contractor’s experience, certifications, and customer reviews. A contractor with a proven track record and the necessary qualifications is more likely to provide high-quality services and meet your maintenance needs effectively. Customer reviews and testimonials can also provide valuable insights into the contractor’s reliability and performance.

Cost Considerations

Understanding the pricing structures and what is included in the contract is crucial for making an informed decision. Electrical maintenance contracts can vary significantly in cost, depending on the scope of services and the level of coverage provided. It is important to ensure that the contract fits within your budget while still meeting your maintenance needs. Comparing different options and negotiating terms can help in finding a cost-effective solution.

Implementing Electrical Maintenance Contracts

Once you have chosen the right electrical maintenance contract, the next step is to formalize the agreement. This involves negotiating the terms, reviewing the scope of work, and signing the contract. Clear communication and thorough documentation are essential to ensure that both parties understand and agree to the terms. A well-drafted contract sets the foundation for a successful maintenance relationship.

Monitoring and Adjustments

Regular reviews and adjustments to the maintenance plan are necessary to ensure its continued effectiveness. Monitoring the performance of the electrical systems and the services provided allows for timely adjustments based on changing needs or emerging issues. This proactive approach ensures that the maintenance contract remains relevant and continues to provide value.

Documentation and Reporting

Keeping detailed records of all maintenance activities and outcomes is crucial for tracking the effectiveness and compliance of the maintenance contract. Comprehensive documentation helps in identifying trends, planning future maintenance activities, and demonstrating compliance with safety and regulatory requirements. Effective reporting also facilitates communication between the client and the service provider, ensuring transparency and accountability.

Conclusion

In summary, electrical maintenance contracts offer numerous benefits, including increased equipment longevity, enhanced safety, cost savings, and improved reliability. By providing structured and regular maintenance, these contracts help maintain the optimal performance of electrical systems and prevent unexpected failures.

Investing in a suitable electrical maintenance contract is essential for ensuring the safety, reliability, and longevity of your electrical systems. Assessing your specific needs, choosing a reliable contractor, and implementing a well-structured maintenance plan can provide significant long-term benefits. By prioritizing regular maintenance, businesses can achieve greater operational efficiency and reduce the risk of costly disruptions.